精密加工設備

我們團隊構建高精密加工設備和管理技術,實現了成品中心偏差精度小於1μm以內的鏡片模具。為了實現極高精度,我們努力提高技術水平。

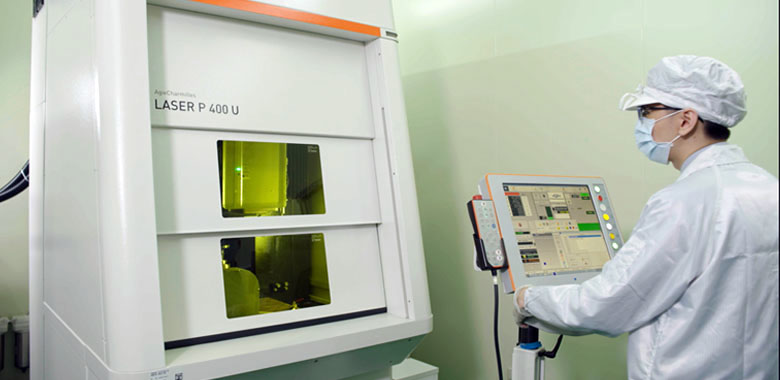

尤其目前已擁有數十台超精密加工機、數台座標磨床、高精度中心加工機、高精密大平磨機及飛秒雷射雕刻機等,以滿足客戶要求。

加工設備-Toshiba FS

|

|

|

加工設備- YASDA |

加工設備-雷射紋理加工 |

儀器設備

高精密模具需要高精度、高準度的測量儀器,以及量測技術才能實現。光學模具不斷提升性能及要求,以提高產品像素與質量。

因現今模仁表面形狀精度設計誤差小於0.05μm ,模具零件的精度要求越來越高,我們也因此建置蔡司三次元(0.4μm ) 、高解析影像式量測儀(0.25μm) 、UA3P表面輪廓儀(0.01μm) 、Compass表面粗糙度儀(0.001μm)等完善的量測儀器,並堅持不懈、努力改進測量和評估技術,以滿足客戶的各種要求。

量測機台-Zeiss三次元

|

|

|

量測機台-Form Talysurf |

量測機台-ZYGO光學輪廓測量儀 |